You are here

Design Development

With Allied Metal Group's knowledge in manufacturing processes and product design, your project is no longer limited to a narrow selection of pre-manufactured products. Allied Metal Group can develop custom design solutions for your project in a variety of materials, including a broad set of metal alloys, while integrating non-metal components, including plastics, glass and electronics, for you without the toil of coordinating among unrelated trades and specialists. You can avoid design mistakes that might otherwise increase manufacturing costs, hinder deployment and construction, prove infeasible or incompatible with inappropriate manufacturing processes, or inadvertently diminish your product's operational lifespan by having Allied Metal Group design for you.

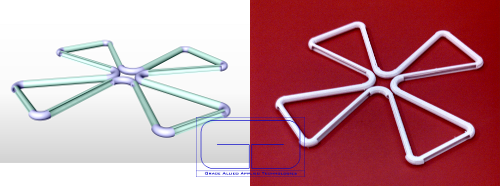

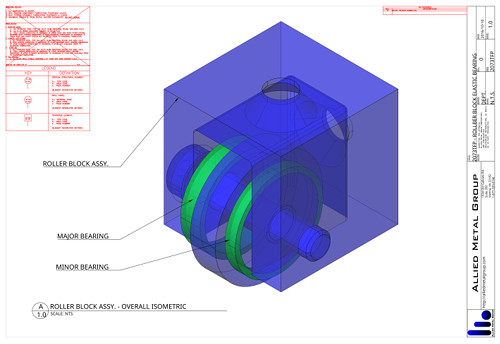

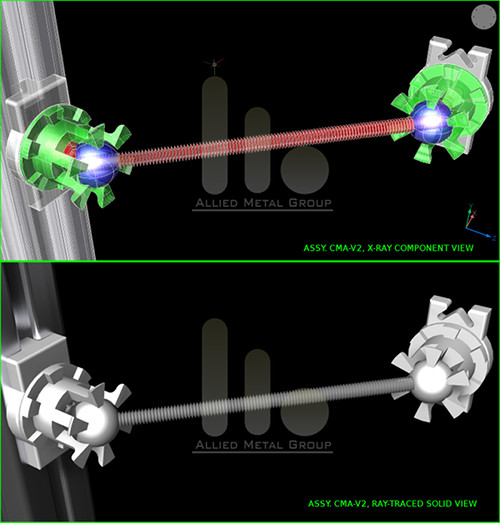

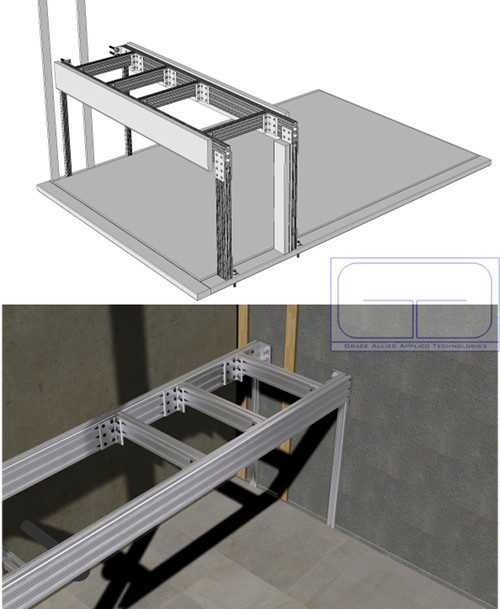

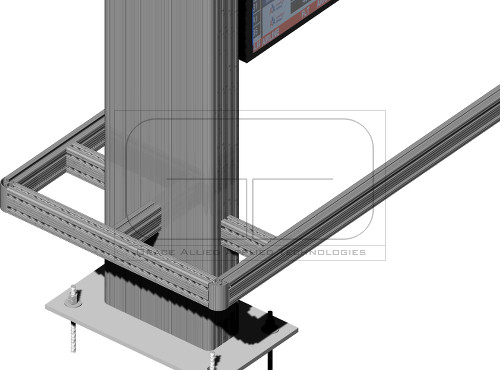

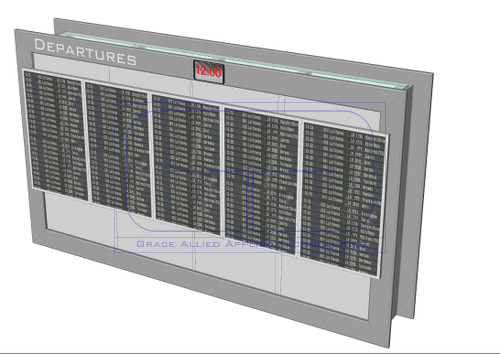

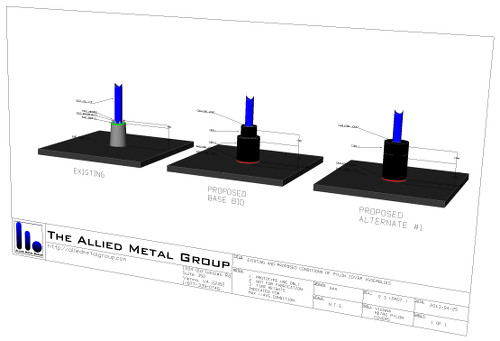

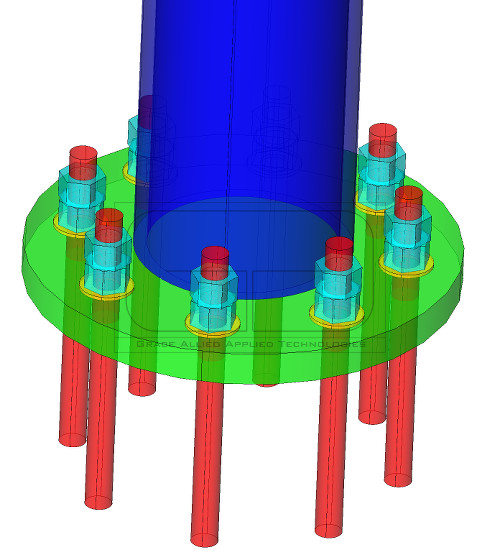

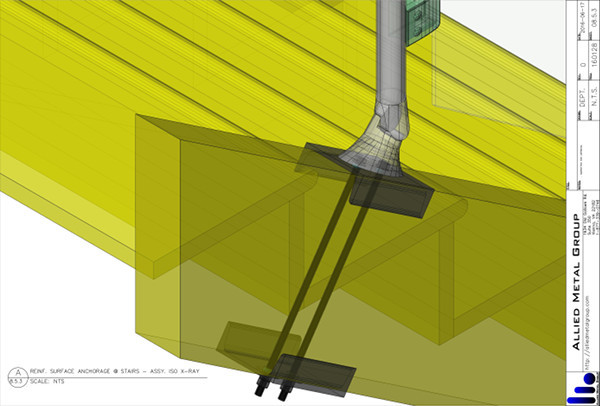

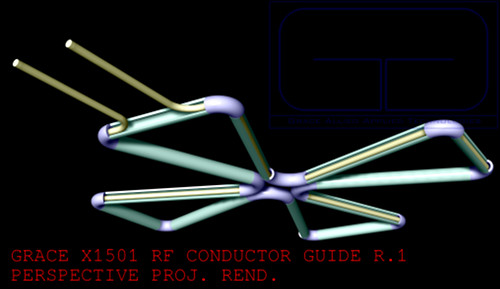

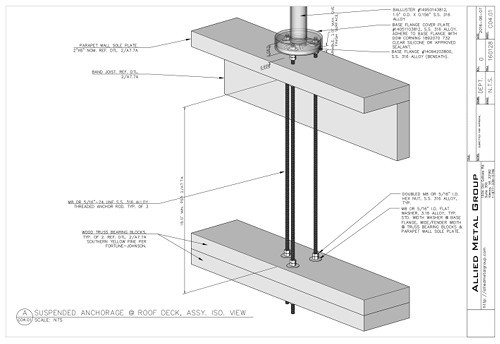

Allied Metal Group uses sophisticated computer modeling and project management systems and can employ a wide range of manufacturing processes appropriate for your design solution.

Design, manufacturing, and construction capabilities:

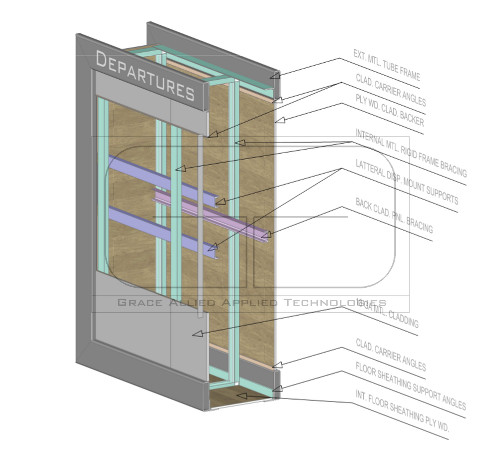

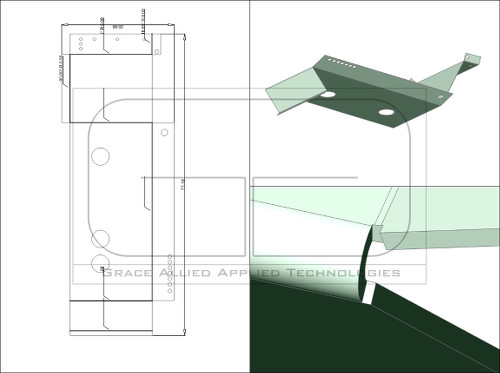

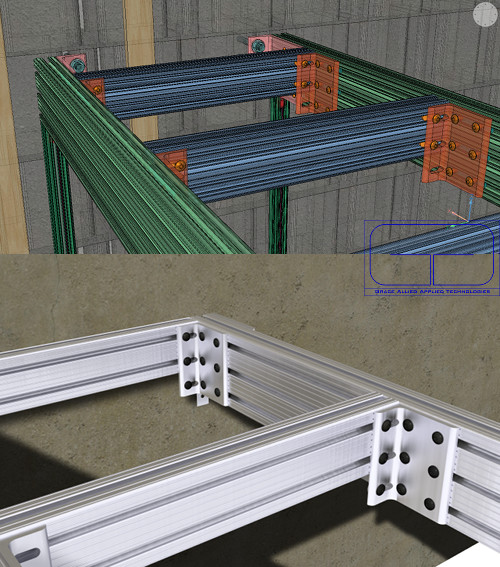

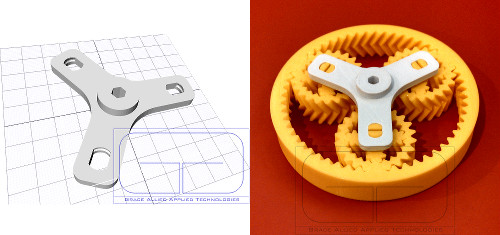

- Manufacturing design, engineering, and integration of composite projects incorporating metals, plastics, glass, and electronics for turnkey solutions

- Complete design development: manufacturing (shop) drawings, 3D computer visualization and modeling, authoring of construction design specification, and final construction

- Engineering to specific structural load criteria including blast and impact loads

- Metal fabrication employing a variety of processes as determined best suited to your project including conventional welding, plasma cutting, laser cutting, and water-jetting in a variety of alloys including:

- Carbon Steel including A36, A53, and A500 alloys

- Stainless Steel including 304 and 316 alloys

- Aluminum including T-3000, T-5000, and T-6000 families of alloy

- Fused deposition modeling (FDM) fabrication of plastics in a variety of polymer chemistries including

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene Terephthalate and Polyethylene Terephthalate Glycol

- Polyvinyl Alcohol

- Polylactic Acid

- Industrial metal blasting

- Industrial metal polishing (#4 through #8 finishes)

- Industrial metal coating and galvanizing

- Final "boots on the ground" deployment for site construction of your finished design solution involving welding, concrete, drilling, and electrical work